Why Leader Ambulance?

At Leader, innovation starts with listening to our customers. We’re not willing to sacrifice vehicle safety, ergonomics or performance. Instead, we find ways to integrate all three.

We’re constantly looking for ways to improve the quality of our vehicles. We take the time to find the right materials and the right high-precision manufacturing techniques. All to ensure every component in our ambulances can stand up to the demanding job you do every day.

Our History

In 1974, Gary Hunter was working at a motor home manufacturer looking to expand its product line. Hunter’s idea to build ambulances on cutaway truck chassis instead of the usual Cadillac station wagon chassis was met with skepticism. But his first efforts were so well received that the ambulance division was soon spun off.

Gary Hunter and the other employees at the newly formed Leader Ambulance plant got to work. The first vehicles they produced were two 1975 Chevrolet G20 Type 2 ambulances with a revolutionary molded fiberglass design that wrapped around to a partial street-side wall.

Leader soon began building Type 3 modular ambulances in addition to van-chassis ambulances. From gasoline shortages of the 1970s to the consolidation of the ambulance industry in the 1990s, we maintained a reputation for producing reliable vehicles built to last. In 2010, Leader became part of REV Group, a holding company comprised of over two dozen industry leading specialty vehicle manufacturers.

We have built our reputation on listening to the people who work in our ambulances day in and day out.

Let us make you a Leader.

Our Factory

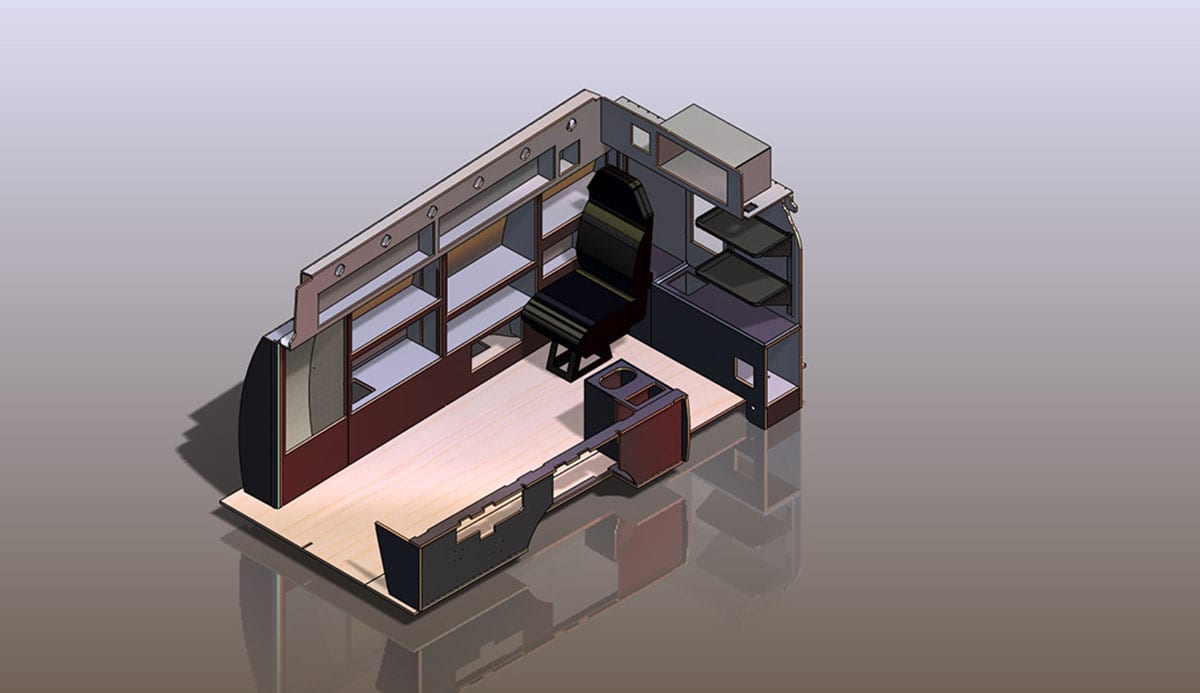

Each vehicle we make starts with a 3D CAD drawing customized to your specific needs.

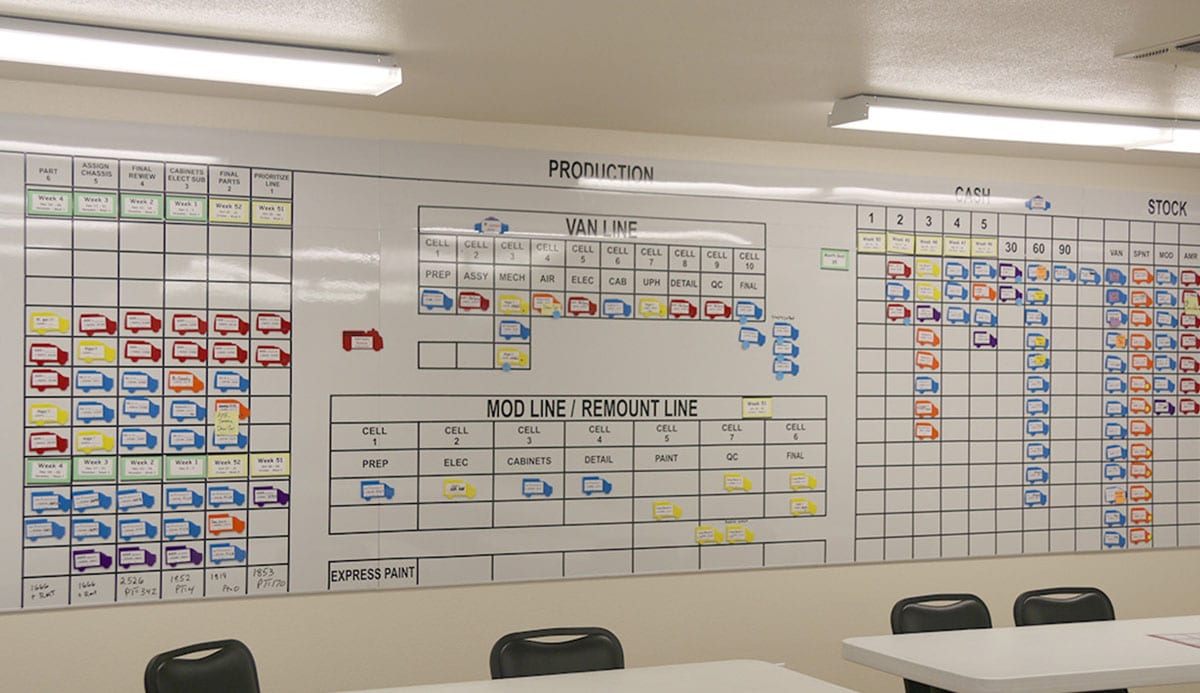

Every step of production is then carefully scheduled to ensure your vehicle is ready by the promised date.

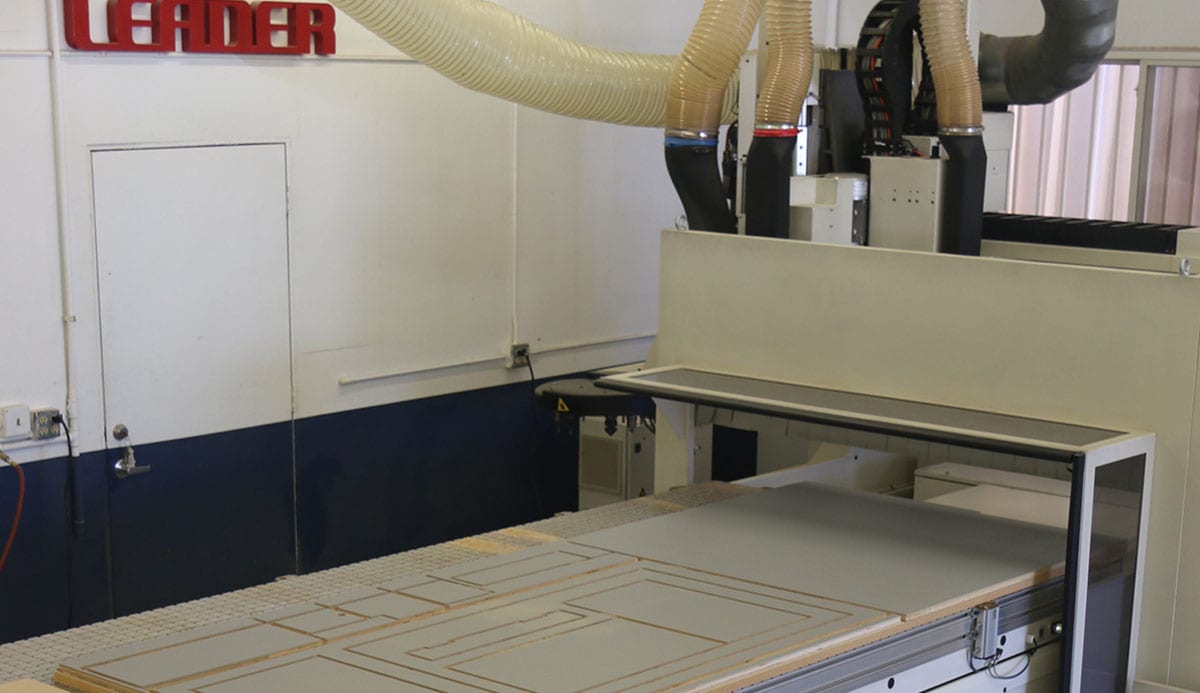

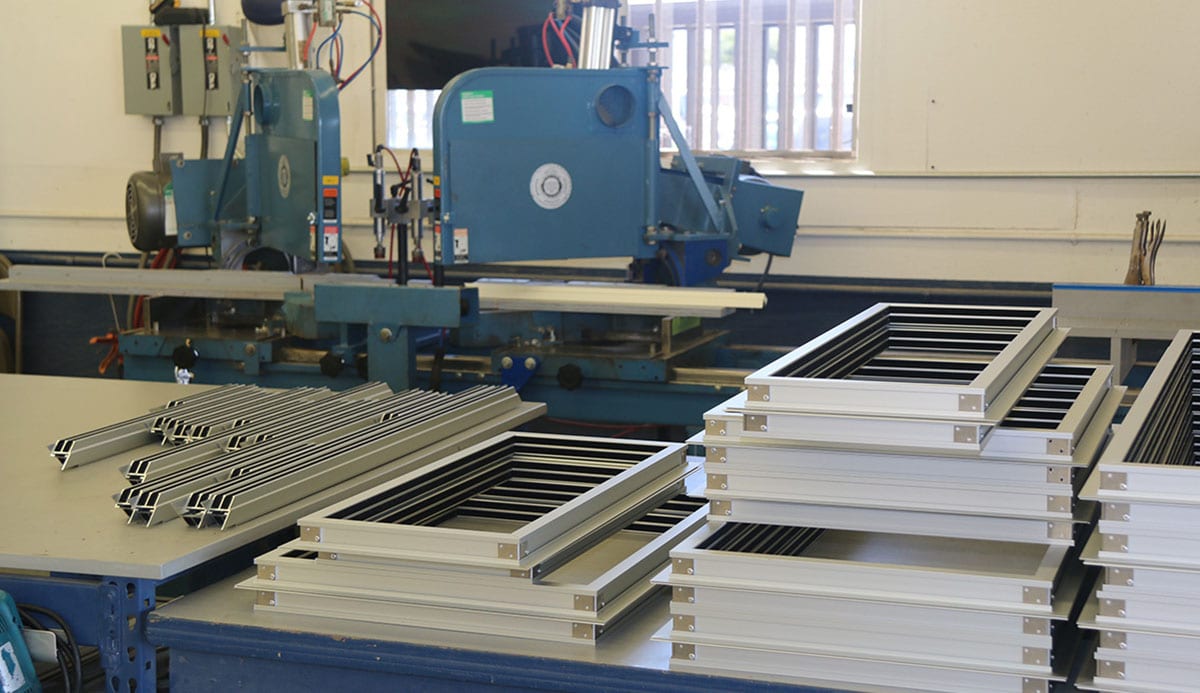

Components are cut to exacting tolerances using our industrial CNC high-speed router and our edge banding machine provides a long-lasting, highly durable finished edge.

At Leader we are constantly looking for new technologies to enhance the quality and durability of the product, like 3D printing, vacuum forming, decal and laser cutting.

Then the assembly process begins. We build our own wire harnesses to ensure an electrical system you can rely on, and even mix our own paint to avoid waste and make sure we match your colors perfectly.

Everything comes together in our state-of-the-art final assembly plant. We provide our personnel with only the best equipment and use lean manufacturing techniques to provide you with the best possible value.

Ask the Leader Ambulance Experts

Have questions about our products or services? We’d love to hear from you.